Harvester chipper chainsaw chains have undergone significant advancements and innovations in recent years, driven by the need for improved efficiency, safety, and sustainability in timber harvesting operations. These innovations aim to enhance cutting performance, reduce environmental impact, and optimize the overall logging process. Some of the notable advancements and innovations in harvester chipper chainsaw chains include:

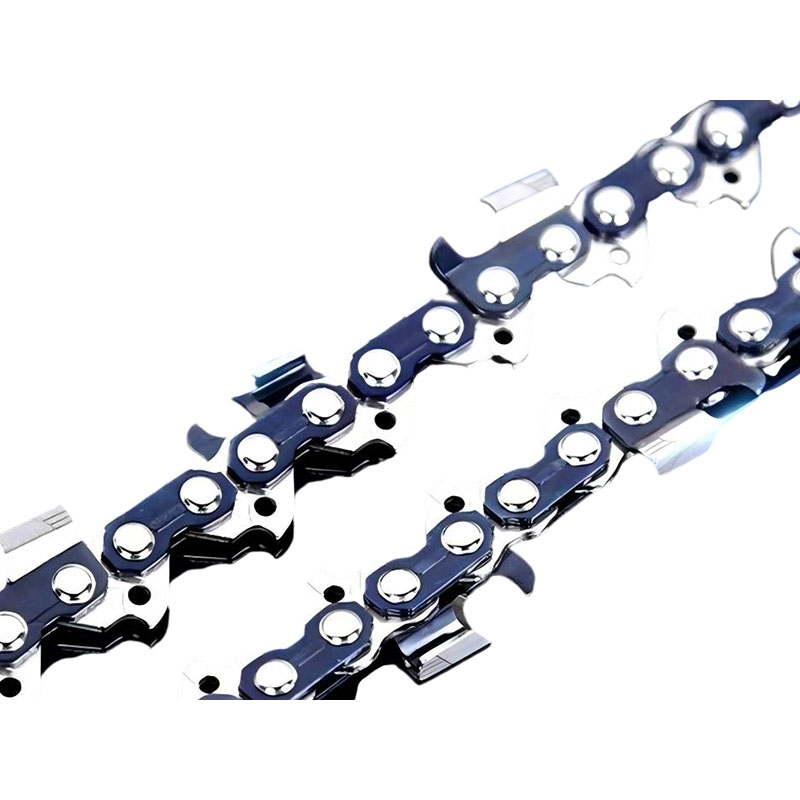

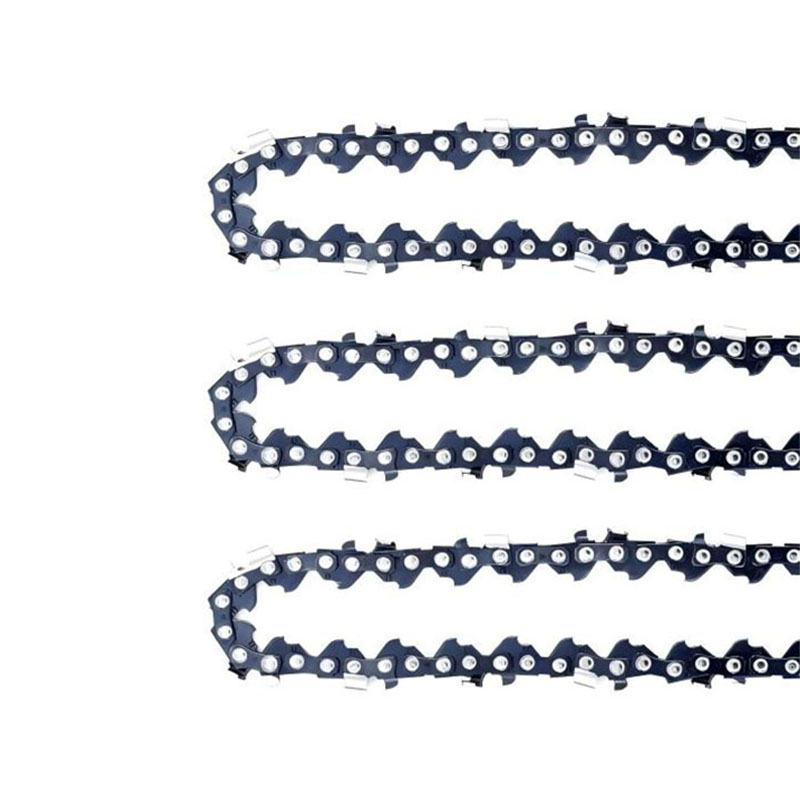

1. Improved Cutting Technology: Advancements in cutting technology have led to the development of specialized chain designs that optimize cutting efficiency. These chains feature advanced tooth geometries, sharp cutting edges, and improved materials to ensure clean and precise cuts through various types of wood.

2. Anti-Kickback Features: Safety is a top priority in timber harvesting. Many modern harvester chipper chainsaw chains incorporate anti-kickback features that minimize the risk of sudden and potentially dangerous kickback events during operation. These features enhance operator safety and reduce the likelihood of accidents.

3. Low-Vibration Designs: Reducing vibration is essential for operator comfort and safety. Chainsaw chains with low-vibration designs use dampening mechanisms and innovative materials to minimize vibrations, reducing operator fatigue and improving cutting accuracy.

4. Enhanced Durability: Advancements in chain materials and manufacturing processes have led to chainsaw chains that are more durable and resistant to wear. This ensures a longer lifespan for the chain, reducing the frequency of replacements and contributing to cost savings.

5. Lubrication Systems: Efficient lubrication is crucial for the proper functioning and longevity of chainsaw chains. Some innovations include improved automatic lubrication systems that ensure consistent oil distribution to the chain, enhancing cutting performance and reducing wear.

6. Digital Monitoring and Control: Some chainsaw chains are designed to be compatible with digital monitoring systems. These systems provide real-time data on chain performance, tension, and maintenance needs. This data can help operators optimize cutting performance and ensure timely maintenance.

7. Customization for Different Wood Types: Chainsaw chains are now being designed and optimized for different types of wood. Whether cutting hardwood, softwood, or specialized materials like frozen wood, chains can be tailored to deliver optimal performance for specific applications.

8. Remote Monitoring and Diagnostics: Some chainsaw chains are equipped with sensors that allow for remote monitoring and diagnostics. This feature enables operators to identify issues and address maintenance needs quickly, minimizing downtime and optimizing productivity.

These advancements and innovations collectively contribute to improved efficiency, safety, and sustainability in timber harvesting operations. As technology continues to evolve, harvester chipper chainsaw chains will likely continue to see further enhancements that enhance their performance and minimize their environmental impact.

English

English

中文简体

中文简体

русский

русский