1. Correct selection and matching

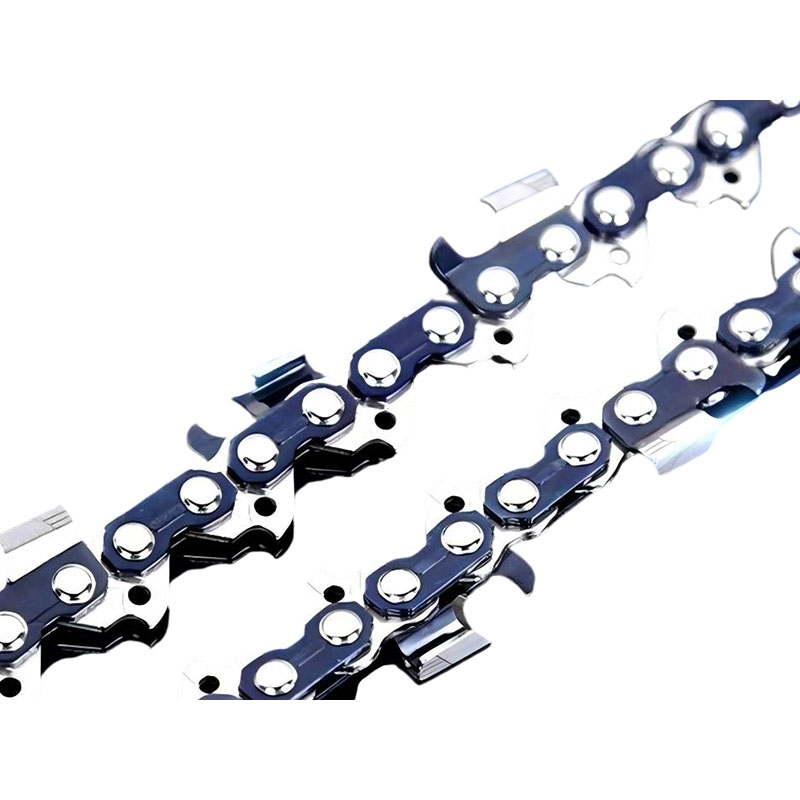

Equipment matching: Ensure that the .080'' Mechanical Lumbering Chain is fully matched with the logging machinery used (such as chain saws) to reduce performance loss caused by mismatch.

Working environment: Select the appropriate chain according to the working environment (such as wood type, humidity, temperature, etc.) to improve work efficiency and safety.

2. Maintenance

Regular inspection: Regularly check the wear of the chain, whether the fasteners are loose, and the lubrication condition, and find problems in time and deal with them.

Cleaning and lubrication: Keep the chain clean, regularly remove impurities such as wood chips and soil on the chain, and use appropriate lubricants for lubrication to reduce friction and wear.

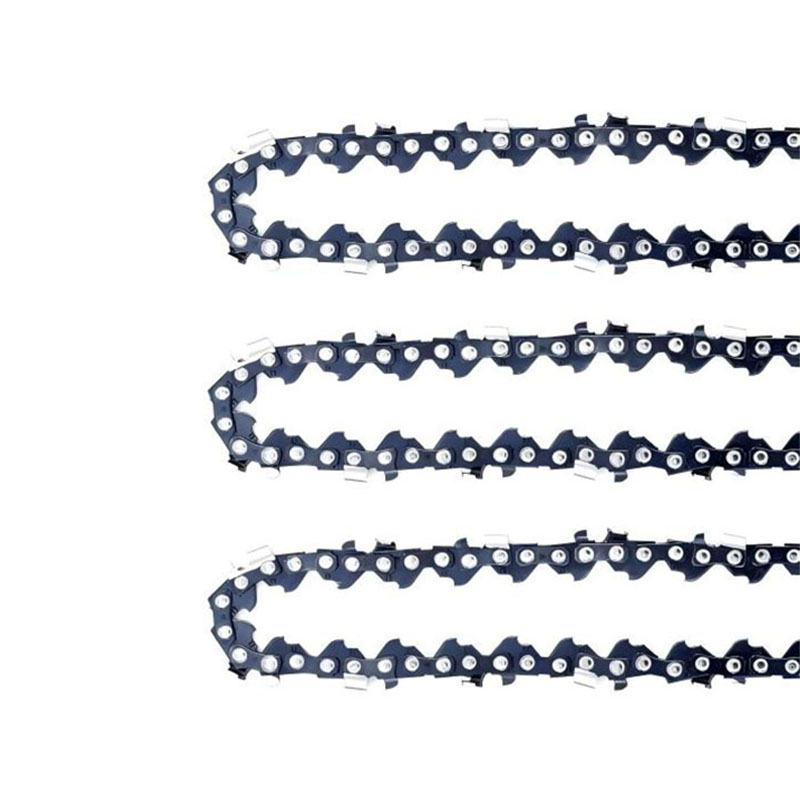

Adjust the tension: Ensure that the tension of the chain is moderate. Too tight or too loose will affect the performance and life of the chain.

3. Reasonable use

Operation specifications: Operators should be familiar with and abide by the operation specifications to avoid chain damage caused by violent operation or improper use.

Load control: Reasonably control the operating load to avoid overloading and other problems such as chain overheating and breakage.

Regular replacement: According to the wear and service life of the chain, replace the aging chain in time to ensure operating efficiency and safety.

English

English

中文简体

中文简体

русский

русский