1. Saw Chain Design and Manufacturing

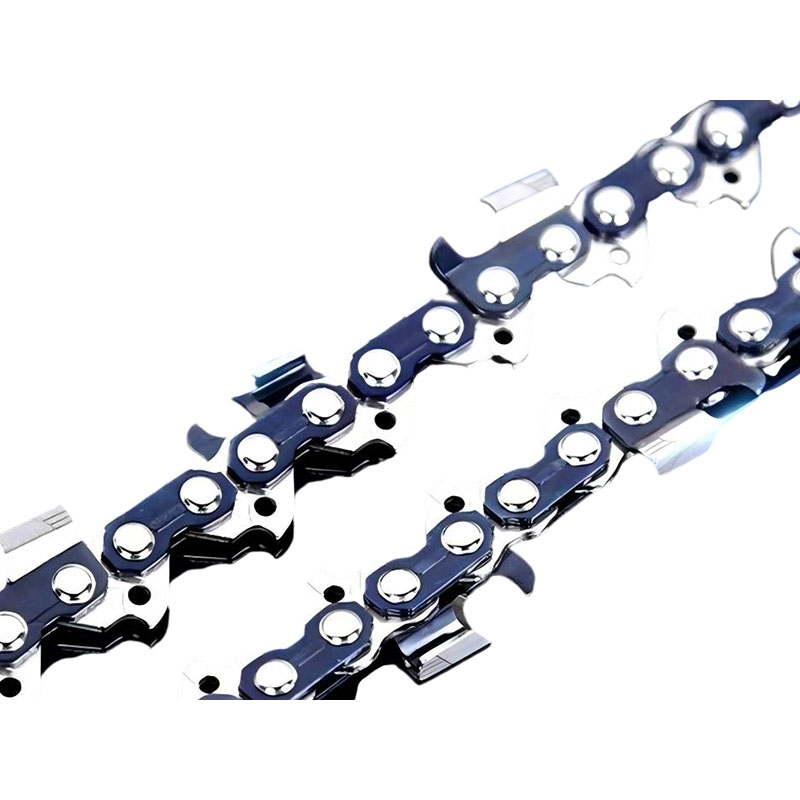

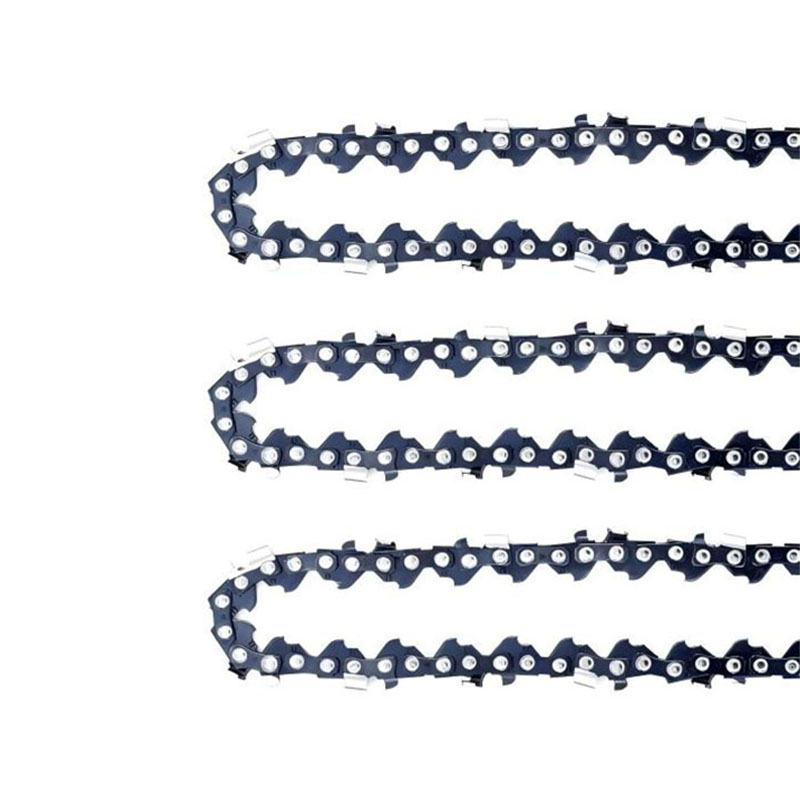

Pitch and Tooth Shape: 3/8'' Pitch helps to ensure that the saw chain remains stable during operation and reduces vibration, thereby improving cutting accuracy.

The tooth shape design of 3/8'' PitchLP Saw Chains is also crucial. Different tooth shapes are suitable for different cutting materials and cutting requirements. The correct tooth shape can cut into the material more effectively and reduce deviations during the cutting process.

Material and process: High-quality alloy materials are the basis for manufacturing high-precision saw chains. These materials have excellent wear resistance, corrosion resistance and toughness, which can ensure that the saw chain maintains a sharp cutting edge during long-term use.

The degree of sophistication of the manufacturing process also directly affects the cutting accuracy of the saw chain. Advanced manufacturing processes can ensure that each link and tooth shape of the saw chain reaches precise standard size and shape.

2. Saw Machine Adjustment and Operation

Saw Machine Adjustment: The adjustment of the saw machine is crucial to ensure the cutting accuracy of the saw chain. This includes adjusting the tension of the saw chain, the position and angle of the guide bar, etc. Correct adjustment can ensure that the saw chain maintains linear motion during operation, reducing deviation and vibration.

Operational skills: The skills and experience of the operator will also affect the cutting accuracy of the saw chain. Skilled operators can more accurately control the cutting speed and depth of the saw chain to ensure the flatness and accuracy of the cut surface.

3. Cutting conditions and materials

Cutting conditions: Environmental conditions (such as temperature, humidity) and cutting speed during cutting will also affect the cutting accuracy of the saw chain. Cutting under appropriate conditions can reduce material deformation and saw chain wear, thereby improving cutting accuracy.

Material properties: Factors such as material hardness, toughness and uniformity will also affect the cutting accuracy of the saw chain. When choosing a saw chain, it is necessary to select the appropriate saw chain type and tooth shape according to the characteristics of the material.

4. Maintenance and care

Regular sharpening: The saw chain will gradually wear during use, resulting in a decrease in cutting accuracy. Therefore, the saw chain needs to be sharpened regularly to restore its sharp cutting edge.

Inspection and replacement: Regularly check the wear and damage of the saw chain, and promptly replace severely worn saw chain parts (such as chain links, guide bars, etc.) to ensure the overall performance and cutting accuracy of the saw chain.

English

English

中文简体

中文简体

русский

русский