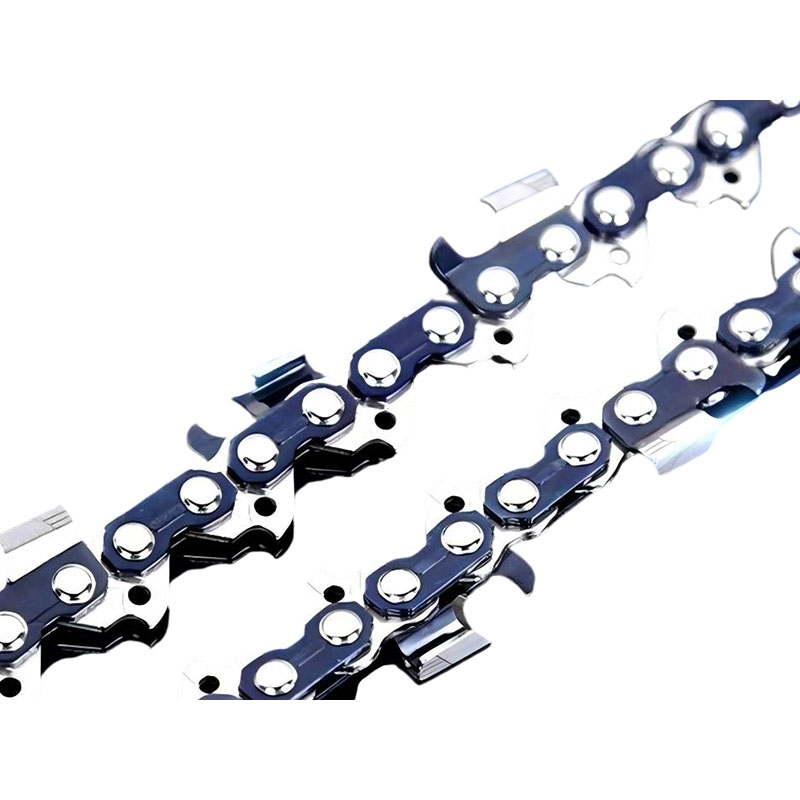

A .080'' mechanical lumbering chain complements precision and efficiency in wooden processing through diverse capabilities and layout factors that cater to the unique requirements of lumbering operations. Here's how this sort of chain contributes to precision and performance:

Optimal Thickness: The .080'' thickness of the mechanical lumbering chain gives a balance among energy and flexibility. This thickness is cautiously chosen to make sure balance during slicing whilst permitting the chain to adapt to the contours of the wood, improving precision in the reducing manner.

Consistent Pitch and Gauge: The mechanical lumbering chain continues a regular pitch and gauge, making sure uniformity inside the spacing and alignment of reducing enamel. This consistency contributes to particular or even cuts, decreasing versions in timber dimensions.

Advanced Cutting Tooth Design: The reducing tooth of the chain are designed for performance and accuracy. Specialized enamel geometry enhances the slicing overall performance, taking into consideration smoother and extra specific cuts with every pass through the wood.

High-Quality Materials: The chain is made from superb materials, consisting of hardened metallic or alloys, which might be selected for his or her durability and resistance to put on. This ensures that the chain continues its sharpness and slicing performance over an extended period.

Reduced Friction and Heat Generation: The design of the mechanical lumbering chain minimizes friction at some stage in operation, reducing warmth technology. This not handiest complements the lifespan of the chain however also guarantees that the wooden is reduce with minimum resistance, contributing to performance inside the slicing system.

Precision Lubrication: Lubrication systems integrated into the chain help hold easy operation via decreasing friction and preventing untimely put on. Proper lubrication enhances the precision of each reducing movement, ensuring accuracy in the shaping of timber merchandise.

Compatibility with Sawing Machines: The .080'' mechanical lumbering chain is designed to be compatible with diverse varieties of sawing machines usually used in wood processing. This adaptability ensures seamless integration into specific sawmill setups, contributing to normal operational efficiency.

Enhanced Chip Evacuation: Efficient chip evacuation functions prevent timber chips and particles from accumulating at the chain, allowing for continuous and uninterrupted cutting. This function improves the efficiency of the slicing procedure and minimizes the need for common stops for preservation.

Optimized Tooth Arrangement: The arrangement of reducing tooth on the chain is optimized to gain efficient wooden removal with every pass. This strategic arrangement contributes to a smoother slicing action and decreases the probability of jams or interruptions in the processing line.

Customization for Specific Wood Types: .080'' mechanical lumbering chains are regularly designed to cater to specific wood sorts and characteristics. Customization options allow sawmill operators to choose chains which are tailored to the demands of processing one of a kind wooden species, making sure gold standard precision in cutting.

Noise and Vibration Reduction: Advanced layout features purpose to limit noise and vibration all through operation. This no longer best enhances the consolation of the operating environment but additionally contributes to the steadiness and precision of the slicing procedure.

Efficient Power Transmission: The mechanical lumbering chain is designed to transmit power effectively from the sawing machine to the cutting tooth. This efficient energy transmission guarantees that every tooth engages with the timber correctly, contributing to the precision of the cutting action.

Adherence to Safety Standards: Safety functions integrated into the chain layout contribute to a stable running environment. These features no longer handiest guard operators however also make sure that the reducing manner is conducted with precision and control.

English

English

中文简体

中文简体

русский

русский