Chipper saw chains are specifically engineered to tackle the challenges posed by tough wood and debris, making them highly effective in demanding cutting applications. These chains stand out due to their distinctive features and design elements that enhance their performance in the face of robust materials.

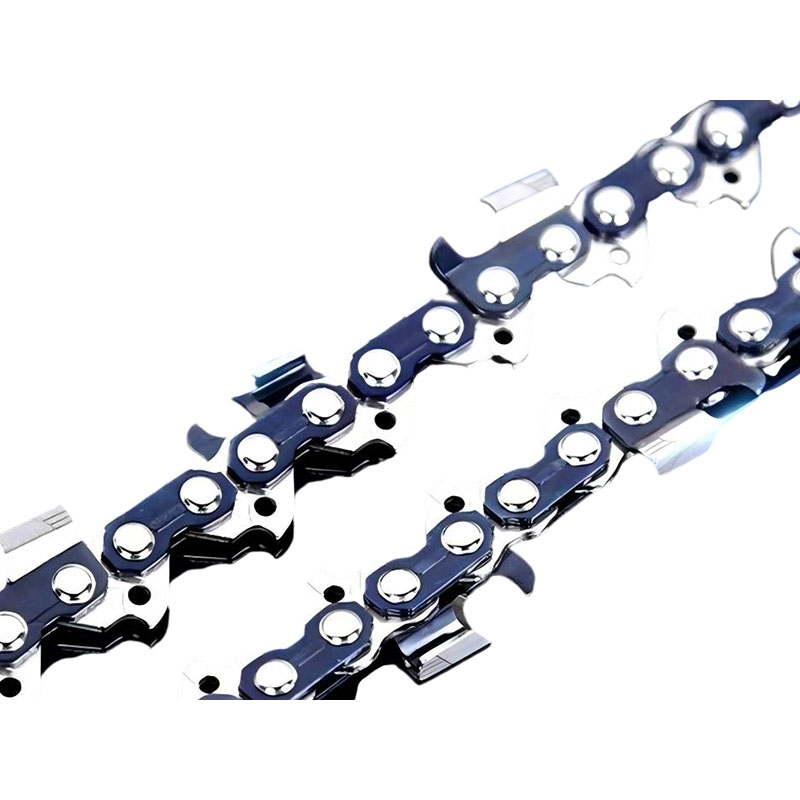

One key feature of chipper saw chains is their aggressive cutting teeth. These teeth are purposefully designed to bite into tough wood and debris efficiently, ensuring effective material removal during cutting operations. The larger and more pronounced cutting edges enable these chains to handle demanding cutting tasks with ease.

The wide kerf design of chipper saw chains is another critical factor contributing to their efficacy. The wider groove or channel created during cutting helps prevent clogging and facilitates the efficient removal of wood chips and debris. This design ensures a smoother cutting process even when dealing with challenging materials.

Durability is a hallmark of chipper saw chains. Constructed from high-quality materials, such as hardened steel, these chains are built to withstand the wear and tear associated with cutting through tough wood and debris. This robust construction enhances the longevity of the chains, making them well-suited for demanding cutting conditions.

Reducing the risk of kickback is a safety-oriented design consideration in chipper saw chains. These chains are engineered to minimize the occurrence of sudden and unexpected upward motions of the chainsaw, providing enhanced safety during cutting operations.

Chipper chains often feature a wider gauge, referring to the thickness of the drive links. This wider gauge contributes to the stability and strength of the chains, allowing them to effectively handle the stress associated with cutting through dense and challenging wood.

The tooth configuration of chipper saw chains is typically chisel or semi-chisel, optimizing them for aggressive cutting. Chisel teeth, in particular, with their sharp points, facilitate efficient material removal, striking a balance between cutting speed and durability.

Consistency in chip size is a notable attribute of chipper saw chains. This feature ensures that the chains produce uniform chip sizes during cutting, preventing the accumulation of debris that could hinder the cutting process. Consistent chip production is crucial for efficient material processing.

Chipper chains are designed to be resistant to impact and fracture. Given the demanding nature of cutting tough wood and debris, this resistance ensures that the chains remain intact and fully functional even when subjected to heavy loads and challenging cutting conditions.

Additionally, chipper saw chains are available in various lengths, providing users with the flexibility to choose the appropriate size for their specific equipment and cutting requirements. This versatility makes chipper chains suitable for a range of wood chippers and cutting applications, further enhancing their adaptability in diverse settings.

Chipper saw chains stand out in their ability to handle tough wood and debris due to their aggressive cutting teeth, wide kerf design, durability, reduced kickback risk, wider gauge, chisel or semi-chisel tooth configuration, consistent chip size, resistance to impact and fracture, and availability in various lengths. These features collectively contribute to the effectiveness and reliability of chipper chains in challenging cutting environments.

English

English

中文简体

中文简体

русский

русский